|

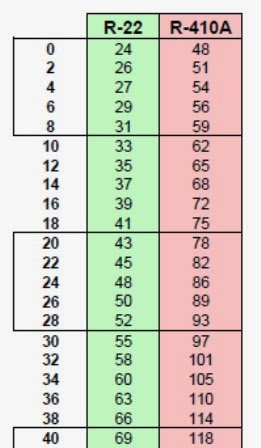

| Q: What is the Saturation Point of R-410A @ 118#? A: 40F |

On the flip side, if we contained all the boiling water in a pressure cooker, we are able to manipulate the boiling point higher by driving up the pressure. This relationship in the refrigeration cycle is measured on our gauges, yet found in the middle of the evaporator and condenser coils on a properly charged system. Fortunately, the most used tool in an A/C Technician's arsenal can no longer be left in the van as the P/T chart is built into the Digital Analyzers these days.

Now, let's say we are able to contain all of the steam being boiled off the pan on the grille. Once all of the water is boiled off at 212F and we make that steam 213F, 214F, 215F; this becomes 1F, 2F, 3F of superheat. Superheat is the amount of sensible temperature we add above the Saturation point. We, as technicians, measure this sensible temperature on the suction/vapor line at the condensing unit. When making the measurement at this popular location, remember that this represents the total superheat. Total superheat is different than the Evaporator Superheat, which would be measured at the outlet of the Evaporator. Pressure drop and temperature gains of a line set can give you a false sense of high superheat on a high load day.

Once you have measured the Sensible Temperature of the Vapor Line, deduct this from the Evaporator Saturation Temperature (Low-Side Gauge Pressure converted to Temperature on your P/T Chart), and the result is your Superheat! Generally speaking, Thermostatic Expansion Valves (TXV's) and their Electronic counterparts (EXV's) maintain decreasing superheat as the efficiency of the equipment rises. Therefor, proper valve operation is critical to prevent compressor failures. TXV's typically maintain between 5F - 25F of superheat. Yet very high efficient system that employ EXV's could be as low as 2F! This gets dangerously close to 0F, representing the possibility of liquid getting to the compressor. Of course, Superheat is how we adjust the refrigerant charge with a fixed metering device (i.e. piston, capillary tube). System airflow and heat content of the air can also play a role in the superheat.

The only reason to attach your gauges on an operable system is to find the Saturation Temperatures of the refrigerant cycle, used to verify proper refrigerant charge. Why does this not get recorded and monitored? Is it as simple as lack of understanding of the single most important aspect to the refrigerant cycle? I know if I did not fully understand something as critical to my job as this, I would be embarrassed and avoid it at all costs. Maybe we just need a little refresher, become a little more confident, and then we will begin protecting compressors thereby avoiding call-backs and warranty losses!